Welcome, beverage company owners! In today’s fast-paced industry, it’s crucial to stay ahead of the competition by improving efficiency and quality. One way to achieve this is by implementing an Enterprise Resource Planning (ERP) system tailored for beverage companies. ERP can streamline processes, optimize resources, and enhance overall productivity. Let’s explore how ERP can revolutionize your operations and elevate your business to new heights.

Streamlining Production Processes with ERP for Beverage Industry

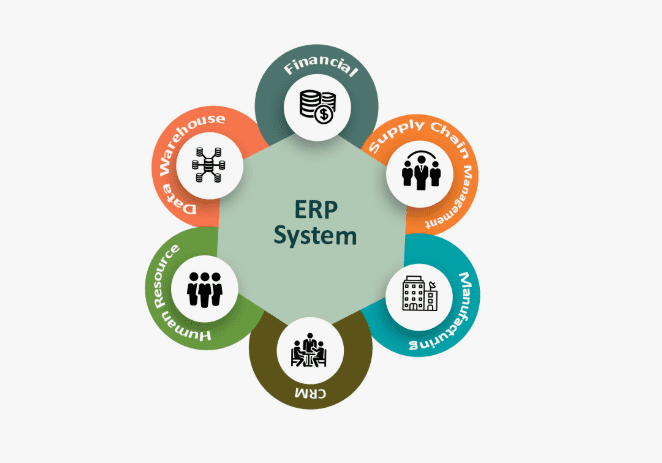

Implementing an Enterprise Resource Planning (ERP) system in the beverage industry can bring numerous benefits, especially when it comes to streamlining production processes. ERP software is designed to integrate various departments within a company, such as inventory management, accounting, human resources, and more, into one centralized system. This integration allows for real-time data sharing and collaboration across different functions, leading to improved efficiency and productivity.

One of the key ways ERP helps streamline production processes in the beverage industry is by providing a comprehensive view of the entire manufacturing process. From raw material procurement to production scheduling to inventory management, ERP systems track every aspect of the production cycle in real-time. This visibility enables managers to identify bottlenecks, optimize production schedules, and make data-driven decisions to improve overall operational efficiency.

In addition to tracking production processes, ERP systems also offer advanced planning and forecasting capabilities. By analyzing historical data, market trends, and customer demand, ERP software can help beverage companies better predict future production needs and optimize inventory levels. This proactive approach can reduce production costs, minimize waste, and ensure that products are delivered to customers on time.

Furthermore, ERP systems in the beverage industry often come equipped with features such as batch tracking, quality control, and compliance management. These tools help ensure that products meet regulatory standards, maintain consistent quality, and adhere to industry best practices. By automating quality control processes and providing real-time insights into production performance, ERP systems help beverage companies maintain high standards and meet customer expectations.

Another significant benefit of ERP systems in streamlining production processes is the automation of routine tasks. Manual data entry, paperwork, and repetitive administrative tasks can be time-consuming and prone to errors. With ERP software, these processes can be automated, reducing the risk of human error and freeing up employees to focus on more strategic activities. This not only improves operational efficiency but also enhances employee satisfaction and engagement.

Overall, ERP systems play a crucial role in streamlining production processes in the beverage industry. By providing real-time visibility, advanced planning capabilities, quality control features, and automation of routine tasks, ERP software helps companies optimize production efficiency, reduce costs, and deliver high-quality products to customers. As technology continues to evolve, beverage companies that invest in ERP solutions will be better positioned to compete in a rapidly changing market.

Enhancing Inventory Management with ERP Systems in Beverage Companies

Inventory management is a crucial aspect of running a beverage company efficiently. With the constantly changing demand for different types of beverages, it is essential for companies to have a system in place that can effectively track and manage their inventory. This is where ERP systems come into play, offering a range of features that can greatly enhance inventory management in beverage companies.

One of the key benefits of using an ERP system for inventory management is the ability to track inventory levels in real-time. This means that beverage companies can always have an accurate view of their current stock levels, preventing stockouts and overstock situations. With real-time data, companies can make informed decisions about when to reorder products, how much to order, and where to allocate inventory.

In addition to real-time tracking, ERP systems also offer advanced forecasting capabilities that can help beverage companies anticipate future demand. By analyzing historical sales data, market trends, and seasonal patterns, ERP systems can generate accurate forecasts that allow companies to optimize their inventory levels and minimize the risk of excess inventory or stockouts. This proactive approach to inventory management can help beverage companies improve their customer service levels and reduce costs associated with carrying excess inventory.

Another way in which ERP systems enhance inventory management in beverage companies is through automated workflows and processes. By integrating all aspects of inventory management, including purchasing, receiving, storage, and distribution, ERP systems can streamline operations and eliminate manual tasks. This automation not only saves time and resources but also reduces the likelihood of errors and inaccuracies in inventory records.

Furthermore, ERP systems provide comprehensive reporting and analytics capabilities that enable beverage companies to gain insights into their inventory performance. By analyzing key performance indicators such as turnover rates, carrying costs, and stock levels, companies can identify areas for improvement and make data-driven decisions to optimize their inventory management processes. This data-driven approach can help beverage companies achieve greater efficiency, profitability, and competitiveness in the market.

Overall, implementing an ERP system for inventory management can bring significant benefits to beverage companies. From real-time tracking and forecasting to automated workflows and analytics, ERP systems offer a complete solution for enhancing inventory management processes. By leveraging the capabilities of ERP systems, beverage companies can improve their operational efficiency, reduce costs, and stay ahead of the competition in the dynamic beverage industry.

Improving Supply Chain Visibility with ERP Solutions for Beverage Sector

Supply chain visibility is crucial for the beverage industry as it helps in tracking products from production to the final delivery to customers. With ERP solutions specifically designed for the beverage sector, companies can greatly enhance their supply chain visibility and efficiency. Here are three ways ERP solutions can improve supply chain visibility in the beverage sector:

1. Real-time Data Tracking: ERP systems allow companies to track their products in real time, from the moment they are produced to the moment they are delivered to the customer. This real-time data tracking helps companies identify potential bottlenecks in the supply chain and take corrective actions to ensure timely delivery of products. By having access to real-time data, companies can make better decisions regarding inventory management, production scheduling, and distribution.

2. Integration of Systems: ERP solutions for the beverage sector integrate all the different systems within a company, such as production, inventory, sales, and distribution. By having all these systems integrated into one platform, companies can easily track products throughout the entire supply chain. This integration also helps in streamlining processes and reducing manual errors that can occur when using separate systems. With all the systems integrated, companies can have a complete view of their supply chain and make informed decisions to improve efficiency and reduce costs.

3. Forecasting and Demand Planning: One of the key benefits of ERP solutions for the beverage sector is the ability to forecast demand and plan production accordingly. By analyzing historical data and market trends, ERP systems can help companies predict future demand for their products and plan production schedules accordingly. This not only helps in meeting customer demand but also in reducing excess inventory and wastage. With accurate forecasting and demand planning, companies can optimize their supply chain, improve efficiency, and stay ahead of their competitors.

4. Collaboration with Suppliers and Distributors: ERP solutions also enable companies in the beverage sector to collaborate with their suppliers and distributors more effectively. By sharing real-time data with their partners, companies can ensure timely delivery of raw materials and finished products. This collaboration helps in reducing lead times, improving inventory management, and ultimately enhancing the overall efficiency of the supply chain. With ERP solutions, companies can create a seamless network with their suppliers and distributors, leading to improved supply chain visibility and performance.

In conclusion, ERP solutions play a crucial role in improving supply chain visibility for companies in the beverage sector. By enabling real-time data tracking, integrating systems, forecasting demand, and collaborating with partners, ERP solutions help companies optimize their supply chain, reduce costs, and deliver products more efficiently to customers. Implementing an ERP solution tailored for the beverage sector can provide companies with a competitive edge and help them stay ahead in today’s dynamic market.

Enhancing Quality Control in Beverage Manufacturing through ERP Integration

Quality control is an important aspect of beverage manufacturing to ensure that products meet the standards set by the company and regulatory bodies. By integrating Enterprise Resource Planning (ERP) systems into the production process, beverage manufacturers can enhance their quality control measures and improve the overall efficiency of their operations.

One of the key ways ERP systems can enhance quality control in beverage manufacturing is through real-time monitoring of production processes. With ERP software, manufacturers can track every stage of the production process in real-time, from raw material procurement to packaging and distribution. This real-time monitoring allows manufacturers to identify any deviations from the standard operating procedures and take corrective action immediately to maintain product quality.

Additionally, ERP systems can help beverage manufacturers streamline their quality control processes by automating tasks such as data collection and analysis. By automating these tasks, manufacturers can reduce the likelihood of human error and ensure that quality control processes are carried out consistently across all production lines. This not only helps to improve the accuracy of quality control measures but also enables manufacturers to identify trends and patterns that can lead to continuous process improvement.

Furthermore, ERP systems can facilitate collaboration between different departments within the organization, such as production, quality control, and distribution. By providing a centralized platform for communication and data sharing, ERP systems enable cross-functional teams to work together more effectively to identify and address quality control issues. This level of collaboration can help beverage manufacturers to implement more proactive quality control measures and prevent issues from occurring in the first place.

Another benefit of integrating ERP systems into quality control processes in beverage manufacturing is the ability to track and trace products throughout the supply chain. With ERP software, manufacturers can assign unique identifiers to each batch of products and track them from production to delivery. This not only helps to ensure product quality and safety but also allows manufacturers to respond quickly to any quality control issues that may arise, such as product recalls.

In conclusion, integrating ERP systems into quality control processes in beverage manufacturing can help manufacturers enhance their quality control measures, improve operational efficiency, and ensure compliance with regulatory standards. By providing real-time monitoring, automation of tasks, collaboration between departments, and traceability of products, ERP systems can enable beverage manufacturers to maintain high product quality and customer satisfaction.

Optimizing Sales and Distribution Channels with ERP for Beverage Businesses

When it comes to running a successful beverage business, optimizing sales and distribution channels is crucial. With the help of ERP systems, beverage companies can streamline their operations, improve efficiency, and ultimately increase their bottom line.

One of the key benefits of using ERP for beverage businesses is the ability to manage sales orders more effectively. By integrating sales order management into the system, companies can track orders in real-time, manage inventory levels, and ensure timely delivery to customers. This not only improves customer satisfaction but also reduces the risk of stockouts and lost sales opportunities.

Another advantage of using ERP for beverage businesses is the ability to optimize pricing strategies. With ERP systems, companies can analyze sales data, consumer trends, and market conditions to determine the most competitive pricing strategies. This allows beverage companies to maximize profits while remaining competitive in the market.

Furthermore, ERP systems can help beverage companies improve their distribution channels. By integrating distribution management into the system, companies can track shipments, manage logistics, and optimize routes for more efficient delivery. This can lead to cost savings, reduced delivery times, and improved customer service.

In addition to streamlining sales and distribution channels, ERP systems can also help beverage companies improve their forecasting capabilities. By analyzing historical sales data, market trends, and consumer behavior, companies can better predict demand, optimize production schedules, and reduce excess inventory. This not only saves costs but also ensures that companies have the right products available at the right time.

Overall, ERP systems offer beverage businesses the tools they need to optimize their sales and distribution channels. By improving sales order management, pricing strategies, distribution channels, and forecasting capabilities, companies can improve efficiency, reduce costs, and ultimately increase their competitiveness in the market.